Why Total Cost of Ownership (TCO) Matters in Machining

Posted on May 23, 2023 by Boston Centerless

Total Cost of Ownership (TCO) is a concept that has been associated with supply chain management and manufacturing for decades. The idea is that the cost of owning a product over its lifespan is broader and more encompassing than simply the initial price paid. Generally speaking, TCO is comprised of two main cost categories: the costs associated with purchasing a product, often referred to as Total Cost of Acquisition (TCA), and the costs associated with operating and maintaining the product through the life cycle.

It is imperative that companies understand TCO, TCA, and operating costs in order to have a clear picture of cash flow and the expected spend profile over time – leading to optimal capital and expense funds management. TCO matters in machining as it enables OEMs to assess purchasing options and make informed decisions based on a comprehensive view of costs – without incurring any “surprise” expenses along the way. The purchase price alone does not determine a good investment as low purchase prices often lead to maintenance and longevity issues – resulting in a higher TCO in the end.

How Boston Centerless Helps Deliver Lower TCO for Our Customers

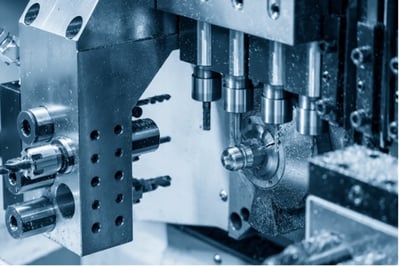

When it comes to precision machining, the team at Boston Centerless knows that quality materials matter. In our experience, a higher investment in precision materials upfront yields a lower, overall TCO. Our precision ground bar delivers a more consistent diameter and straightness with no variations – enabling machines to operate more efficiently with fewer stoppages for maintenance and retooling, increasing productivity and OEE. Additionally, our Skilled Material results in less machine vibration and wear and tear – resulting in higher quality finished products with less scrap waste. Boston Centerless’ Skilled Material allows our customers to more than offset premium material cost by dramatically reducing the need for skilled machine operators to deal with material quality issues, while maximizing machine uptime and throughput. In addition, Skilled Material enables lights-out manufacturing and ultimately lowers the total cost of CNC Swiss operations. For these reasons, it is crucial that OEMs consider Total Cost of Ownership when making purchasing decisions for machinery and raw materials.

How Total Cost of Ownership Often Leads to Re-shoring

At Boston Centerless, we know the value of a robust supply chain. In recent years, many OEMs have relocated manufacturing closer to home to strengthen their supply chain – a process known as reshoring. Reshoring is simply bringing manufacturing back from overseas. Over the past several decades, many North American OEMs transitioned manufacturing offshore, typically to locations in Asia such as China, to take advantage of perceived lower costs and other anticipated benefits. While some costs such as labor may be lower with offshoring, many OEMs are realizing that reshoring is a much more competitive and attractive option when total cost of ownership and brand reputation are considered.

When it comes to reshoring, Boston Centerless delivers superior quality, streamlined logistics, and excellent proximity across the U.S. – all of which provide OEMs with more control over their supply chain. In fact, we recently opened a second manufacturing plant located in Fort Wayne, Indiana that offers our customers even shorter lead times and lower costs, especially those located in the Central and Western regions of the U.S.

Do you have a process that demands the consistency and reliability of precision ground bar material?

Contact us today to learn about our precision grinding expertise and why our solutions deliver a lower TCO than the competition.

Key Acquisition and Operating/Maintenance Costs to Consider when Estimating TCO

Acquisition costs include more than the purchase price. As a general rule of thumb: TCA costs are upfront expenses including the initial purchase price as well as any costs incurred to get the product to the point of use. Below are some common acquisition costs beyond the purchase price.

- Logistics & Transport: the logistics and transport activities may be straightforward or very complex. The costs may include packaging, warehousing, freight rates and shipping, and delivery fees. Import fees and insurance costs should also be included.

- Installation: once the product arrives on site, there may be installation, testing, or commissioning costs to factor into the TCA.

- Managing Inventory: inventory management costs should also be included in TCA estimates as optimal inventory levels lead to lower warehousing and transportation costs. Conversely, inefficiencies within the inventory management system affect overall cash flow and lead to higher TCA.

- Overhead: every TCA includes some degree of overhead costs.

- Margin Stacking: each member of the supply chain typically adds a layer of cost or profit margin, a process referred to as “margin stacking.” OEMs should minimize the number of suppliers in the supply chain, removing the “middle man” and leading to significant savings. This is why it pays to choose an integrated product and service provider, like Boston Centerless, that offers a complete manufacturing solution with fewer vendors along the supply chain.

The other major component of TCO is operating and maintenance costs, which are typically easier for OEMs to estimate. Operating expenses should include labor and the utilities/energy required to operate the equipment. As for maintenance, expenses that should be factored into TCO estimates include labor, replacement parts, and the necessary parts or tools. Assumptions will need to be made for maintenance intervals and durations and it is important to include the impact on production during the equipment downtimes for maintenance activities (i.e., lost production cost). Various personnel costs may also need to be included in TCO calculations. While personnel costs may be categorized as acquisition or operating costs depending on the nature of the activity, it is important that OEMs account for these expenditures somewhere in the TCO estimate. Examples include time spent on purchasing (including research and vendor selection, order placement, expediting, and on-going vendor communications), logistics support, accounting, initial and on-going training for personnel as well as 3rd party or in-house technical support.

About Boston Centerless

Boston Centerless provides solutions that enhance our customer’s manufacturing processes. With 65 years of precision grinding expertise, we grind the tightest tolerances in the industry. We have proven experience with an extensive range of materials, and our manufacturing solutions include:

- AccuRod® Precision Bar

- BC Medical Grade

- Grinding Services

- Value-Added Services

- Material Testing & Validation

- Supply Chain Management

- SwissAssist

Contact us today at (781) 994-5000 to see how with your next precision bar materials project, or click here for a quote.