Metallurgy Behind Metal Grinding: How Does it Work

Posted on August 02, 2022 by Boston Centerless

When it comes to grinding metal, there is much more than meets the eye. In fact, there’s a whole body of science behind metal grinding called metallurgy. Metallurgy is the study of the chemical and physical properties of metals, alloys, and related compounds.

The better your grinding company understands metallurgy, the more effective their grinding service will be at achieving high degrees of precision and tight tolerances. In this article, we take a closer look at metal composition in terms of the strength of metallurgical structures, the Rockwell hardness scale, the fundamentals of the metal grinding process, and what sets Boston Centerless apart when it comes to precision metal grinding.

Metal Composition: The Strength of Metallurgical Structures

While there are many different types of metals and alloys, the structural composition of all metals is crystalline in nature. The atoms of a crystal are arranged in a lattice pattern. Different types of metals have different degrees of deviation from a perfect lattice pattern, which translates to different degrees of strength of each metal.

Conceptually speaking, perfect lattice structures have no defects and would actually be rather weak and ductile. In reality, metals are not perfect and, as a result, they have defects in their crystal structures, which translates to grains in metal materials. Interestingly, these defects include energy that makes the metal stronger and less ductile.

Metal compositions can be thought of as aggregates of grains and within each grain is this crystalline structure. Defects can be single point defects within the lattice structure, or lines through a grain, called dislocations. Moreover, grain boundaries themselves are also defects and are termed planar defects. The movement of the dislocations allows for the movement of metal. The result is that decreasing dislocation movement strengthens the metal. It is with this understanding of the strength of metallurgical structures that we turn our attention to the time-tested system for measuring the hardness of metals.

Rockwell Hardness: Measuring the Hardness of Metals for Over 100 Years

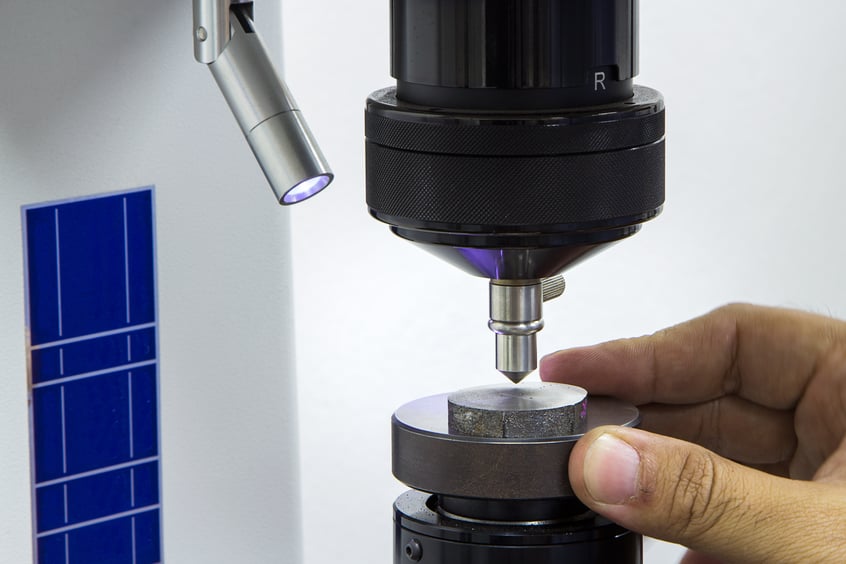

Rockwell hardness is a measure of how resistant a metal material is to penetration and permanent deformation from another material. Rockwell testing is a non-destructive metallurgical test that determines how hard and strong a metal such as steel truly is. On the Rockwell hardness scale, the higher the number, the harder the metal is. Conversely, the lower the Rockwell number is, the softer the metal is.

The Rockwell hardness scale was created by brothers Hugh M. Rockwell and Stanley P. Rockwell. They were metallurgists at a Connecticut ball bearing factory in the early 1900s. The Rockwells saw a need to test the metal strength of their ball bearings quickly and accurately.

In 1914, the Rockwell testing method was patented by Stanley Rockwell. Subsequently, in 1919, the patent was amended to include the Rockwell scale chart. There are 30 different scales on the patented Rockwell scale chart. The Rockwell system replaced earlier metal testing systems, such as the time-consuming Vickers test and the destructive Brinell test.

Rockwell testing applies static force to a metal surface for a defined period of time using precise measuring instruments. These measurements are entered into a specific mathematical formula, which computes a corresponding number on the Rockwell scale.

The standard Rockwell testing method uses static indentation, which involves two distinct tests. The first test applies a small amount of pressure using an indentation tool called an indenter. The indenter makes a very small impression on the metal being tested. The depth of this impression is measured and recorded as Value A. The second test in the Rockwell testing method applies a heavier force to the same spot on the metal’s surface. This heavier force produces a penetration level that is measured and recorded as Value B. Once Value A and B are determined, Value A is subtracted from Value B, and the result is then translated by the testing technician into a value on the Rockwell scale.

Are you looking for a world-class precision metal grinding company? Boston Centerless is the industry leader in precision grinding solutions for a wide variety of materials.

Contact the professionals at Boston Centerless to learn more about how we can help you achieve the tightest tolerances possible on your grinded parts.

The Fundamentals of the Metal Grinding Process

Metal grinding is a machining process that removes metal from the surface of an object or part. In its most basic sense, grinding can be thought of as abrading, wearing away by friction, or sharpening. The grinding process uses a rotating abrasive wheel to remove the metal. Metal grinding wheels are made up of projected abrasive particles, which are elongated metal chips varying in size, usually from 0.4 to 0.8 mm.

Metal grinding has a wide variety of uses. Some of the most common uses include:

- Removing metal from a workpiece to bring its dimensions within tolerances post-rough finishing and heat treatment

- Used as a substitute for machining certain hard surfaces which are difficult to machine by high-speed steel tools or carbide cutters

- Grinding threads to achieve tight tolerances and a better finish

Metal grinding is an effective method for cutting hardened steels. Parts are first machined to shape in annealed condition, which leaves only a small amount of metal for grinding depending upon the size, shape, and propensity of the material to warp during high-heat exposure.

Grinding produces extremely smooth finishes, which are ideal for use at contact surfaces such as in medical applications. Grinding wheels are also wide, which prevents marking during feeding. These advantages of metal grinding result in extremely accurate dimensions and achievement of complex profiles for high precision applications.

Grinding wheels are similar to milling cutters. They consist of abrasive particles, bonding material, and voids. The abrasive particles project outward and act like cutting tool tips when removing metal.

The grinding process produces an extremely high temperature at the tip of the abrasive particles when cutting. For fine grinding, temperature can be reduced by decreasing both wheel speed and chip thickness. For normal grinding, temperature can be reduced by decreasing the wheel speed, but not by decreasing chip thickness. Additionally, fluid is used in grinding to decrease the workpiece temperature and reduce wear and tear of the grinding wheel.

Properly managing temperature during grinding is critical to ensuring high-quality finished bars or components. If temperature is not properly managed, microscopic structural changes on the surface of the product such as cracks can occur, thus compromising precision and tolerances.

Boston Centerless is the Leader in the Precision Metal Grinding Industry

When it comes to metal grinding at Boston Centerless, we are experts at precision grinding material to extremely tight tolerances. AccuRod provides precision ground bar materials to customer specifications.

The GrindAll division focuses on precision grinding bar material and round components supplied by our customers. Our centerless grinders can handle pre-machine to finish grind operations, using the thru-feed, in feed, or profile method. We can also take care of material testing and validation, straightening, and heat-treating.

We can grind the following materials:

- Alloy and Carbon Steel

- Aluminum

- Medical Alloys

- Plastic

- Red Metals

- Special Alloys

- Stainless Steel

- Titanium

Look to Boston Centerless for all of your precision metal grinding needs. Contact Boston Centerless at 781.994.5000 to learn more today.