The Economic Benefits of Using Precision Ground Bars in Manufacturing

Posted on November 04, 2025 by Boston Centerless

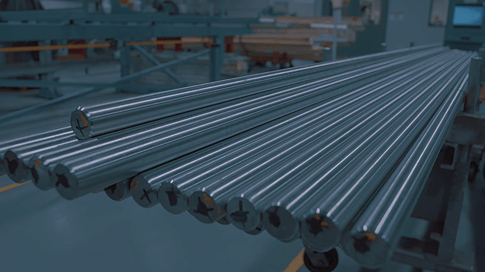

Precision ground bar stock is often written off as ‘expensive’ or ‘overpriced’. Yet, when it comes to manufacturing your product, can you really afford to be using cheap material? While precision bar shows its full price up front, bar stock of a lower quality comes with hidden costs that waste valuable resources, complicate machining, and can negatively impact customers’ perception of your brand. In today’s blog, we’re going over the economic benefits of using ground bar shaped by centerless grinding in precision manufacturing.

Waste Less Material, Machine Space, and Manpower

If you’ve ever had to machine your stock material down to size before you actually start machining a part, you know exactly how tedious the process can be. While it may seem like just another step in the process, the truth is that additional material preparation is a triple threat against your shop’s productivity. It generates unnecessary waste in the following three categories.

Material

The most apparent of the three is wasted material. Although you may be shaving off only a fraction of an inch at a time, that waste adds up over the days, months, and years. If you’re working with a low cost plastic, this may seem inconsequential—but if you’re working with a high cost superalloy, chances are we’ve got your attention. There are ways to collect and recycle waste material chips, but unless you’re creating your own stock on-site at your facility, collecting waste material isn’t going to do much good for your bottom line.

Machine Space

As if letting material go to waste wasn’t bad enough, you can’t get any of that machine time back either. Whenever a machine is occupied for material prep, that’s valuable time and real estate that you’re not utilizing on a value-added activity—in this case, creating your product. Ideally you want to minimize material prep since it doesn’t add any inherent value to the finished product. However, when you’re working with low quality stock and the only other option is to skip out on prep and risk ruining your cutting tools or machine, there’s a clear winner.

Manpower

Finally, think about who’s at the helm of these operations. When material prep is a must, you’re not just wasting material and machine space. You’re wasting manpower, too. Just like with the machines, would you rather have your people fussing with getting the material ready, or would you rather them be able to set the material and get started without a second thought?

Thankfully, there’s one easy way to avoid these types of manufacturing waste. By starting with precision ground bar stock (or precision blanks, in some cases), you can cut material prep steps entirely. Not only does this make your shop comparatively more efficient to how it was before—it can also put you one step ahead of the competition.

Improve Machinability

That’s just where the economic advantages of precision ground stock start. Once the material is set in the machine, it can make a world of difference for your shop’s efficiency.

Precision ground bar is defined by excellent uniformity in its diameter, roundness, and straightness across the entire length of the bar. Standard or low quality stock may have variations in these features that can make it difficult or more time consuming to machine. By eliminating these variations, precision bars can help your team work faster with less likelihood for manufacturing errors or reject products.

Not only is this good for your productivity—it’s good for your machines, too. Precision ground material puts less wear on your machine and your cutting tools, so you can spend less time on maintenance and tool changeover and more time creating quality parts. This keeps your uptime at a maximum, and helps extend tool and machine life for greater cost efficiency.

Want to learn more? Discover how bar straightness impacts machinability in the blog,

Precision Bar Straightness: What It Means and Why It Matters.

Reduce Product Defects

Are you struggling with product defects? Are your customers reporting premature failures and calling in warranties? These issues could be the result of poor material quality. Depending on what your ground bar manufacturing partner or supplier provides, your material could potentially be riddled with defects that are invisible to the naked eye. There are two types of defects to check for in round bar stock: surface defects and internal defects.

At Boston Centerless, we test materials for both types of defects. Our on-site quality analysis lab uses methods like Ultrasonic Testing and Eddy Current Testing to validate the integrity of your material, inside and out. We conduct material testing and validation on all stock that comes through our vetted network of ground bar manufacturing partners, and we can also test any customer provided metals and plastics as well.

Boost Product Longevity

Better quality material often results in a better quality end product. That means when you opt for bar stock that’s been ground with precision and validated to be defect-free, your final product quality will likely improve. This isn’t just about how the product looks and performs fresh off of the production line. It’s about how it performs throughout its life cycle, whether that’s months, years, or decades-long. Customers appreciate a product that they can rely on to perform exactly as they expect, time after time. With that in mind, investing in material quality is like investing in your customers’ experience—and if it’s great for the customer, it’s great for your business.

Find out how centerless ground bar can help you save in the long run.

Contact us today for an expert analysis or rapid quote.