5 Reasons Why OEMs Rely on BC for Precision Machining

Posted on May 09, 2023 by Boston Centerless

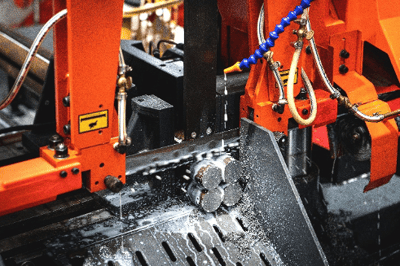

At Boston Centerless, we serve a range of sectors from medical to aerospace to automotive. The commonality across these industries is the need for high precision bar materials to optimize the performance of their products. OEMs depend on Boston Centerless’ outstanding product quality as well as our reliability as a supplier. Below are 5 key reasons why OEMs rely on us for their precision machining needs.

1. Experience

At Boston Centerless, our history and proven experience set us apart from other suppliers. Having been in the grinding business since 1958, we are known for providing precision bar material with the most exacting tolerances in the industry. Not only is the diameter tolerance important, but the dimensional tolerance of roundness and straightness is as equally important to the smooth production of component manufacturing.

Our proprietary processes have been developed over the years, and methodically passed down to ensure that our reputation for being the most consistently superior producer of precision ground bar products and grinding services would remain intact as the company grew and expanded. You will experience the results of our highly skilled and experienced people built into every precision ground product you receive. Our expertise and relentless commitment to quality distinguish us from other suppliers.

2. Integrated Product and Service Provider

Integration is a huge differentiator as most other machine shops simply cannot provide the range of in-house services and precision products that we do. At Boston Centerless, our value-added services include heat treating, straightening, laser marking, and material testing and validation. When combined with our precision grinding operations, these steps can reduce costs, decrease time to market, increase productivity, enhance quality, and improve responsiveness for our customers.

Over time, OEMs often find they have developed a large supply chain that can be challenging and time-consuming to manage. Working with an integrated supplier, like Boston Centerless, enables OEMs to consolidate their supply base, resulting in a healthier supply chain. When partnering with an integrated service provider, value-added services become an extension of the precision grinding process – delivering a complete manufacturing solution. As your one-stop-shop, Boston Centerless has the capabilities, capacity, quality assurance standards, and resources to support all of your precision machining needs. Read our short article for more details on how outsourcing to an integrated shop streamlines your supply chain.

CNC Swiss machining is one of the fastest growing sectors in the machining world. However, there are often two challenges that OEMs face with CNC Swiss processes: lack of skilled labor in the workforce to keep these machines running and constant market pressure to reduce costs. This is where Boston Centerless is able to help. We created Skilled Material, which is a concept that encompasses many facets of raw material properties, manufacturing processing and industry know-how to optimize your CNC Swiss operations – while reducing your overall cost of production.

Skilled material bar enables operators to run multiple machines at once - or even unattended - offering the opportunity for lights-out manufacturing without concern for quality issues. In addition, due to less vibration and wear on the machine, the use of precision ground bars leads to increased equipment and tool life as well as increased uptime. In short, Skilled Material helps solve both of the common problems OEMs have with CNC Swiss machining. Skilled Material is a unique offering at Boston Centerless and is not found at any other supplier.

Looking for a precision grinding partner that is physically located closer to your operating facilities?

Contact Boston Centerless today to learn more about our new Fort Wayne, IN manufacturing plant that offers outstanding lead times and cost reductions for our Central and Midwest customers.

4. Lean Experts

As a recipient of the Shingo Prize Northeast Silver Medal for Excellence in Manufacturing, the culture at Boston Centerless empowers every employee to suggest, evaluate and implement improvements through various lean process tools. A recognized industry leader in Lean Manufacturing, we often open our plant to other companies interested in maximizing their continuous improvement efforts and benchmarking our lean initiatives.

Our lean culture isn’t a one-time project – it is a continuous improvement mindset that permeates our entire business. We seek to minimize, or eliminate, waste wherever it exists in our operations in order to improve efficiency and quality, adding value for our customers. From receipt of material to manufacturing, packaging and shipping, through purchasing and customer service, every effort is made to assure perfect quality, on-time delivery and 100% compliance to customer specifications.

5. SwissAssist

It is no secret that there are many advantages to CNC Swiss machining – the efficiency, quality, and uniformity offered by these machines is unparalleled. However, as noted, one of the biggest challenges to entering Swiss machining is the lack of skilled operators to run the Swiss machines. To address this issue, Boston Centerless developed an industry-leading CNC Swiss machining training program called SwissAssist. Our SwissAssist program provides CNC machine operators with next-generation PartMaker SwissCam training, as well as CNC Swiss machine training.

Our SwissAssist program offers hands-on, comprehensive training ranging from basic Swiss machining principles all the way to the most complex Swiss machining processes including thread whirling, helical milling, polar milling, and more. Our unique SwissAssist training is one of the top reasons OEMs rely on us. Visit our website for additional details on our SwissAssist program.

About Boston Centerless

Boston Centerless provides solutions that enhance our customer’s manufacturing processes. With 65 years of precision grinding expertise, we grind the tightest tolerances in the industry. We have proven experience with an extensive range of materials, and our manufacturing solutions include:

- AccuRod® Precision Bar

- BC Medical Grade

- Grinding Services

- Value-Added Services

- Material Testing & Validation

- Supply Chain Management

- SwissAssist

Contact us today at (781) 994-5000 to see how with your next precision bar materials project, or click here for a quote.